Table Of Content

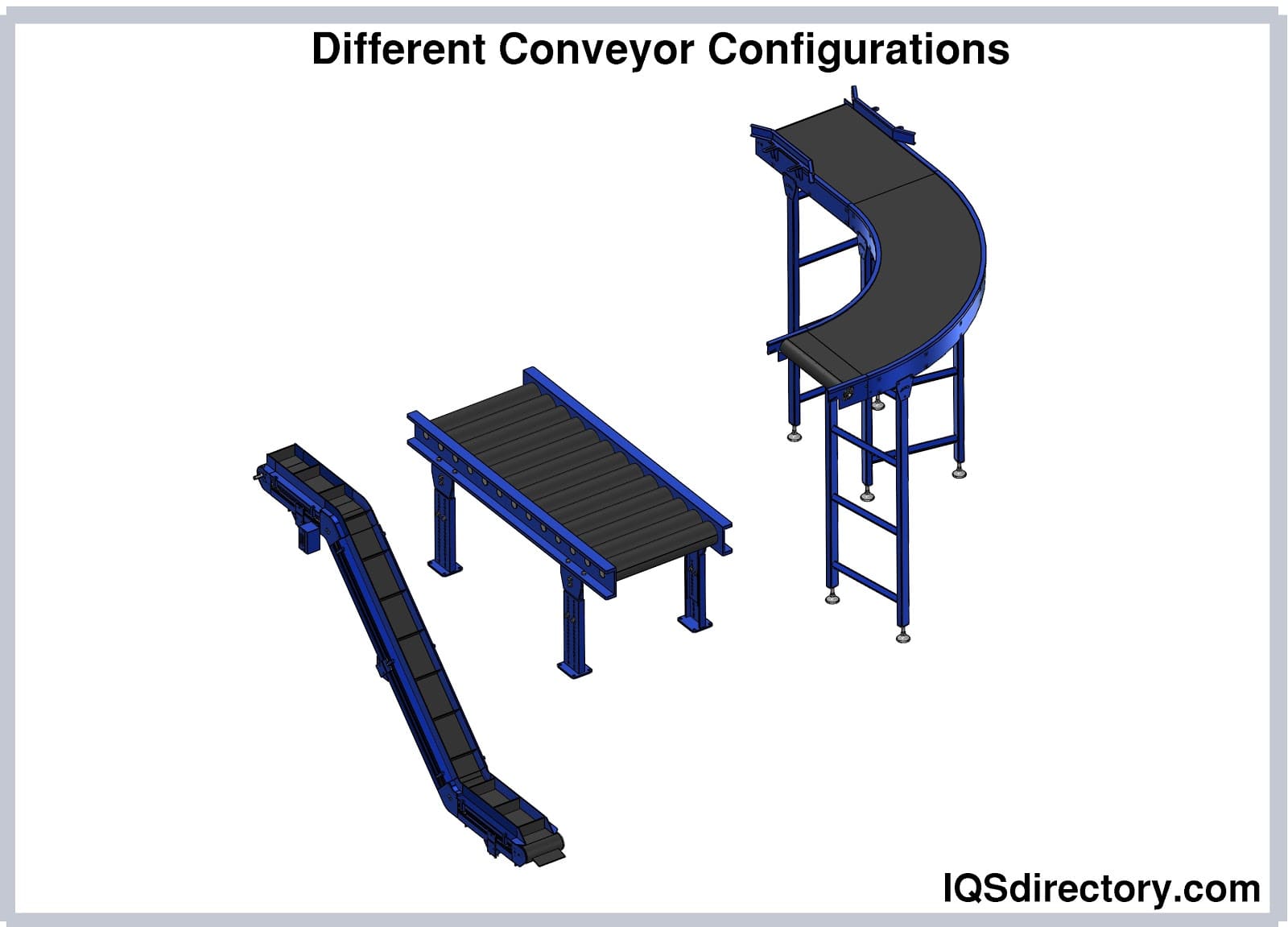

Motorized conveyor belts are ideal for industrial use as they are more reliable and efficient — the driving unit for such systems would include the motor bracket, electrical drive and any counter bearings. An intelligently designed conveyor system can improve production outputs, reduce the need for manual handling, increase factory space and even lower operational costs. In our experience, conveyors can be an excellent way to quickly improve the operation of a facility. The design and implementation of conveyor systems exemplify the synergy between various engineering disciplines. Mechanical engineering principles are fundamental in designing the physical aspects of the conveyor, such as structure, rollers, belts, and drive mechanisms.

Bespoke Curved Conveyor Systems - Agg-Net

Bespoke Curved Conveyor Systems.

Posted: Fri, 13 Mar 2020 07:00:00 GMT [source]

Overhead Conveyors

Durable belting material and good use of support rollers are necessary for conveyor belt systems in these industries. These case studies illustrate the versatility and adaptability of conveyor belt systems in addressing specific industry challenges. Through innovative design and customization, conveyor systems continue to play a pivotal role in enhancing operational efficiency, safety, and reliability across diverse sectors. To ensure safe and efficient conveying, it is essential to consider the size, shape, weight, fragility, and orientation of the product being transported. These factors play a crucial role in determining the type of conveyor and its specifications.

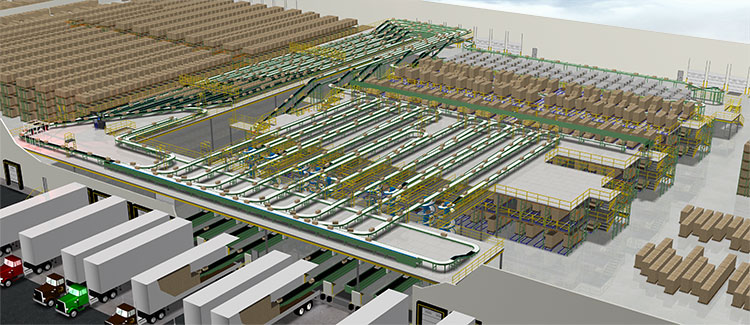

Beam trolley conveyors

The complexity and versatility of these systems mirror the advancements in engineering and technology, highlighting the importance of interdisciplinary collaboration. Smart conveyor systems integrate sensors, IoT connectivity, and data analytics to optimize performance and enable predictive maintenance. These systems can monitor various parameters, such as belt tension, temperature, and vibration, in real-time. By analyzing this data, manufacturers can proactively identify potential issues, prevent breakdowns, and maximize production output. Productivity measures the rate at which goods or materials are produced within a given period. Improving productivity indicates increased production output and efficiency.

Maximizing Production Output: How Optimal Conveyor Belts & Systems Design & Manufacturing

Taking these into account ensures that conveyor systems can handle the product properly without damaging it, leading to increased efficiency and reduced maintenance costs. Aside from the construction of the conveyor mechanism itself, you will want to make sure your unit utilizes the correct type of motors for the load you are moving. They turn a sprocket on the drive pulley, so they provide power and speed to the conveyor. The simplest conveyor definition is a person or thing that transports something. In industry, it generally refers to a track, either motorized or not, which carries parts or products from one location to another in warehouses, assembly lines, or distribution centers. A conveyor is a piece of mechanical handling equipment that makes light work of moving things, setting a pace for operations, and preventing injury to workers.

When your operation outgrows its current warehouse, DCS will work with you to evaluate and assess potential solutions to meet your storage, handling, distribution, and fulfillment needs. This is because platform may be a 50kg load on the loadcell before product is applied but the load passing over could account for 50kg of extra weight. When setting up the system the 50kg static platform load is removed from the calculation (tare weight). Dynamic weighing conveyors measure the weight of the product as they pass a point on a conveyor – they can be used to show total product weight and instantaneous weight passing that point.

Before knowing the detailed description and working of the conveyor system let us see know its history and how the device development happened. The initial and fundamental conveyor belt invention took place in the 19th century. While in the period 1892, Thomas Robins invented a conveyor belt that was mainly employed for carrying ore, coal-related materials.

Conveyor systems,believe it or not, are a very environmentally friendly way to transport yourproduct through tough terrain or protected land. Conveyors cause a minimaldisturbance in the area versus creating new roadways for truck hauling. A tilter automatically tilts product at a preset angle that can reach nearly 90 degrees.

Energy Efficiency Label Highlights Continental Conveyor Belt Energy Savings - Continental

Energy Efficiency Label Highlights Continental Conveyor Belt Energy Savings.

Posted: Thu, 27 Oct 2022 07:00:00 GMT [source]

Additionally, conveyor systems are almost always an integralpart of a more extensive, multi-stage production process. As such, the entire operationmust be considered, or you risk creating an unbalanced plant with bottlenecksthroughout. Designed Conveyor Systems has been providing custom material handling solutions since 1982. Designed Conveyor Systems has the expertise to update your current conveyor design, add any new capabilities you may need, or even design a custom conveyor system from scratch. The size of materials to be moved will need to be considered once you have a general idea of the type of conveyor system you will use. This includes the weight of each object, how many you plan to move per hour, how far they will move, and so on.

We can help you design a system for peak performance today, but can be modular to expand as readily as your business. Lineshaft conveyors are a great type of roller conveyor that is driven by a shaft underneath the rollers, which connects to rings that power the rollers. They are a very safe option for when you have people working on the line, because the rollers will stop if fingers or clothing make their way into the gaps. The amount of horsepower needed will vary with each application, depending on your load and speed requirements. Most businesses run on 3phase AC power supplies, and there are three main types of 3 phase conveyor motors.

Ensures Protection for Employees – When carryback gets accumulated under the belt, it creates damage to the employees where they might slip and fall down when they walk across the material. Maintaining belts as clean will protect the conveyor system from the early aging of devices and increases the durability of system components. Wire mesh conveyors are made from woven metal wires and are ideal for applications that require high airflow or liquid drainage. They are commonly used in industries such as baking, drying, and cooling, where ventilation is essential.

These are used for shipping huge stone materials in the mining domain across tunnels over distances. Let us consider one type of coal mine conveyor system which is elevating type. Whereas in the case of some conveyor systems like movable walkways and grocery store conveyor systems, these are straight, and the sections have to be turned for delivery of items to the specified location. To these turns, they have cone shape of wheels or rotors where these wheels allow the system to turn or bend without tangling. Conduct regular inspections to identify any signs of wear, damage, or misalignment.

The need to clean while the conveyor is running to maintain production often trumps the need for shutting down and following Lockout/Tagout/Blockout/Testout procedures. When choosing a conveyor belt for your business, take the time to research your options carefully. This is so you can rest assured knowing that you have made a wise investment. The main purpose of a conveyor system is to move objects from one location to another. The design allows for movement of objects that are too heavy or too bulky for humans to carry by hand.

No comments:

Post a Comment